Abrasives & Grinding Wheels

Abrasives & Grinding

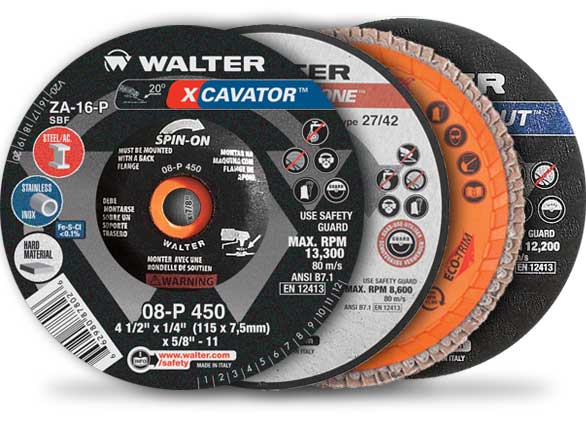

Walter Surface Technologies

Walter abrasive solutions are manufactured with the highest quality of materials and process in the industry. Whether you are using a grinder, table saw, circular saw or chop saw, we have right cutting, grinding, blending, sanding, finishing and cleaning tools for your job.

When you are cutting, grinding, blending, sanding, cleaning or finishing we are consistently setting the standards for high performance abrasive products. Our abrasive solutions are made to outlast and outperform, from start to finish.

At Walter, our goal is to provide “only the best” to you. This means we develop only the best abrasive products, services and solutions so that you can ensure that you have the best cutting, grinding, blending, sanding, finishing and cleaning abrasives for your project. Because we know, when you are building the best, you only deserve the best!

Abrasives & Grinding

CGW - Camel Grinding Wheels

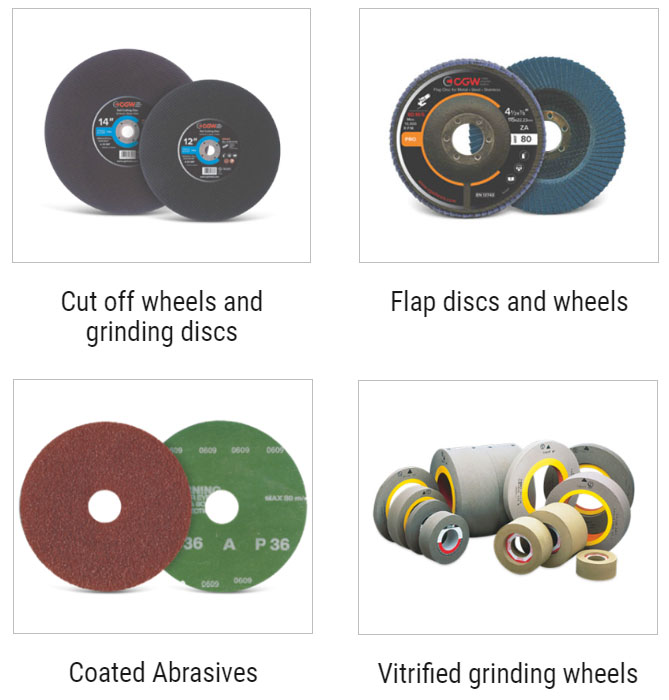

A Leading manufacturer and supplier of abrasive products world wide. Resin and vitrified bond grinding wheels, cut-off wheels, flap discs & coated abrasives. Cutting-edge grinding solutions, Unconditional commitment to the quality and safety of our products.

CGW's advanced abrasive technology based on years of experience and ongoing research insures our unconditionally commitment to innovation and to the quality and safety of our products.

Bonded abrasives are made by incorporating abrasives grains into a matrix, which can be resin and fillers or vitreous materials. Usually, such abrasives contain porosity which helps to control the thermal aspects of the process.

Coated abrasives are abrasive grains incorporated or cloth backing. The formulation and choice of additives are usually a closely guarded secret of the manufacturer.

Abrasives & Grinding

FlexOvit

BEST-IN-CLASS PERFORMANCE | Smoother cuts. Longer life. Flexovit abrasives grind smooth, cool, remove metal faster and last longer than the competition. Our best-in-class performance is the direct result of our commitment to quality materials, processes and research.

MADE WITHOUT COMPROMISE IN THE USA | Flexovit wheels are manufactured in the USA with the best raw materials on the market. There’s no compromise on that - for our customers, only the best will do.

ISO CERTIFIED FOR CONSISTENT QUALITY | Flexovit is the first North American abrasive manufacturer to achieve ISO certification. With Flexovit, you can count on receiving the same high-performing abrasive product every time.

Abrasives & Grinding

Metabo

Engineered in Germany, Metabo's premium line of power tools are designed for professional users to provide the highest level of safety, reliability and performance. Metabo manufactures both corded and cordless power tools, as well as a full line of abrasives and accessories for metalworking, concrete and many other industrial and construction applications. In every Metabo tool, there is traditional German engineering ingenuity. Our service, tailor-made to your requirements, also makes us a strong partner for the industrial sector. Perhaps the most vertically integrated power tool manufacturer, Metabo controls the quality of its manufacturing processes with the tightest tolerances.

Abrasives & Grinding

Allison Abrasives

Allison Abrasives manufactures abrasive cutting wheels engineered for the fastest and cleanest cut possible. From 3” to 67” in diameter, our wheels can cut any type, size, and temperature of metal.

Our specialty is custom engineering “the right” wheel for the job with minimum costs per cut. If you need cutoff wheels that eliminate burn and burring, we’ll develop one that will do that in the most cost effective manner possible.

Allison Abrasives’ cutoff wheels in rubber and resin-rubber for wet cutting applications. We also produce resin bonded cutting wheels in cold and hot press configurations that can cut any type, size and temperature of metal.

Our in-house team of experts and fine distribution network are ready to take care of you.

We Represent The High-Quality Brands That Benefit Your Business